Service, Repairs & Parts

Your concern – our task:

We take care, so do our long term partners.

Boiler Service & Repairs all boilers

ALFA LAVAL AALBORG

Spare Parts

ALL OUR MAKERS

Oil Condition Monitoring

PARKER

Service & Repairs | Alfa Laval Aalborg

Boiler Service & Repairs for all boiler brands

After years of wear and tear, the performance of boiler and waste heat recovery systems can degrade enough to impair operations or cause unplanned shutdowns.

Alfa Laval Repair for boilers restores your equipment to good-as-new condition and can even be used to extend boiler life. It can be a more cost-effective option than buying new parts, or in the worst case buying and installing a new boiler.

Alfa Laval can perform boiler repair on a scheduled or emergency basis, including during your vessel’s normal operation.

All brands

Repair of all brands Alfa Laval has served the boiler industry for a century, working with all aspects of boiler design, manufacture, inspection and service. Combining this comprehensive experience with technology from today’s boiler programme, we can repair and upgrade all types and brands of boiler and waste heat recovery equipment.

Boiler Performace Audits on fixed prices

A Boiler Performance Audit provides insight into your boiler system’s performance and safety. In addition, our boiler specialist will optimize its combustion settings during the audit, which could lead to significant fuel savings.

Condition Audit and Inspections performed before any major repair to assess wear and identify the causes of poor performance.

And the best: In selelected ports close to Alfa Laval service hubs we will attend on a favorable fixed price covering all working and travelling costs in a lump sum.

24/7 Service Hotline

- A service hotline that works 24 hours.

- For urgent matters between 8:00 – 16:00 local time please call +45 99 30 45 45

- For urgent matters between 16:00 – 8:00 local time please contact our 24 hours phone +46 46 36 77 00

- Or us the common service email address: marine.service@alfalaval.com

Spare Parts

Alfa Laval supplies genuine, high-quality OEM spare parts for all Alfa Laval Aalborg boilers. Original, up-to-date spare parts are shipped within 24 hours to any corner of the globe. To make this possible, Alfa Laval maintains full stocks of the most common consumables and spare parts at centralized location.

For customer in Europe on dedicted team in specialists will be at your disposal under: AalborgParts.Europe@alfalaval.com

Alfa Laval Aalborg Service Kits

Spare parts on board whenever you need them.

Service kits are a smarter choice than ordering individual spare parts, both for your peace of mind and for your operating budget. With the right parts on hand – wherever and whenever you need them – you can avoid lengthy stops, last-minute decisions and rush order fees.

Alfa Laval offers a complete range of dedicated Aalborg Service Kits that help you plan your maintenance costs and save over the long term.

We organize or supply spare parts for our partners:

Azienda Chimica Genovese

MGPS, ICCP

Alfa Laval Aalborg

Steam Boilers, Thermal Oil Boilers, Inertgas Systems

API Marine

Tank Measurement, Valve Remote Ctrl.

Atlas Incinerators (G&O Group)

Incinerators

dinotec

Poolwater Treatment

DM Alscott

HVAC&R, fans

Pompe Garbarino

Centrifugal Pumps

Idromar International

Watermakers

Hugo Lahme

Pool Outfitting

Leistritz Pumpen

Screw Pumps

Netzsch Pumpen

Rotary Piston Pumps, Excenter Pumps

Nordhavn Marine

Aux Engine, Emergency Engines

Parker

Oil Condition Monitoring

Spare Parts | Dan Marine

Your marine supermarket for parts and services

Shanghai Dan Marine specializes in the location, distribution and supply of marine diesel and auxiliary engine spare parts, deck machinery equipment, as well as general provision stores for the international marine industry. The company supplies genuine replacement parts from licensed manufacturers and qualified subcontractors. Providing high quality products is our core philosophy and a majority of the products are approved by classification societies.

The Service Division of Shanghai Dan Marine provides professional and efficient maintenance, repair and commissioning services for vessels docking in and visiting PRC ports.

Shanghai DAN Marine is offering a wide-range marine requirements:

- Spare Parts & Equipment for engine room, deck and bridge

- Main Sourcing in China, Korea and Japan

- Genuine Spare Parts and OEM Parts

- Replacement Units of Asia and European Manufactures

- Large warehouses in Shanghai, Qinagdao and Guangzhou for stock items & owners disposability

Product groups

Engine spares (Main & Aux Engines)

Deck equipment

Pumps & Compressors

Own built garbage compactors, bulker grabs

Electrical equipment

Ship stores for Chinese ports

24/7 boarding Services to CE while dry docking

Offcical re-seller for main & auxiliary engine makers

Main engine spares, as the agent for DMD, (MAN B&W and WARTSILA SULZER engine maker in China), CMD (HHM China and MITSUI Japan JV factory for MAN B&W for main engine).

Aux. Engine spares, Dan Marine is the official dealer for YANMAR engine. Included the service and overhauling. As well as supplying the DAIHATSU , MAN aux. engine spares from ZJMD, CME, SHANXI, ANQING.

Locations

If you need further information, please contact us or have a look at: www.dan-marine.com

Oil Condition Monitoring | Parker

Parker Kittiwake the specialist!

Parker provides on-line and on-site solutions for the condition for monitoring the condition of fuel and lube oils in your onboard engines and equipment.

The sensors and measurement devices provide a quick and thorough basis for decision making to keep your machinery running efficiently for longer lifetime. Used Oil Analysis – Easy to Use & Cost Effective – Fuel & Lube Oil Testing Made Easy

Offering sensors, kits and even laboratories (using ferrography, magnetometry and colourimetry) to ensure correct operation of machinery without interrupting the process.

DIGI Cell:

Portable Unit to measure BN, Water in Oil, AN, Salt, Insolubles and Viscosity in a few minutes.

Ferrous Wear Meter (FWM):

Portable kit for measuring the ppm of wear metal (Fe) by means of magnetometry. PPM value displayed in 2 sec.

Cold Corrosion Test Kit:

Provides users with the non-metallic iron content of used scrape-down oil, a phenomenon often encountered by ship operators due to slow steaming and low temperatures in M/Es.

Bunker Fuel Testing

Sampling and testing of fuel for quality and quantity. By testing the fuel quality at the point of delivery, we ensure that the fuel meets the density requirements essential for good bunkering practice.

Heated Viscometer:

Suitable for testing the viscosity of both residual fuel & lube oil from a wide variety of sources. Testing the viscosity of fuel oil is important for verifying that the correct grade of fuel is being supplied, for calculating combustion performance, and for adjusting fuel handling and injection systems. Lube oil viscosity of is the most important property, with the correct viscosity providing optimum film strength in system clearances, with minimum friction losses and leakage.

Compatibility Tester

The Compatibility Tester is perhaps the most useful and underrated tool available for testing fuel oil compatibility and blends. This kit provides a quick and useful tool for engineers faced with the need to mix or blend residual fuel oil or to establish the stability of a new bunker supply.

Cat fines

Cat fines cause damage to fuel injection equipment. The fines are particles of spent aluminum and silicon catalyst produced during the catalytic cracking process in the refinery, and vary in both in size and hardness. If not reduced by appropriate treatment, the abrasive nature of these fines will damage the engine, particularly fuel pumps, injectors, piston rings and liners, leading to unexpected damage, costly repairs, and unplanned downtime

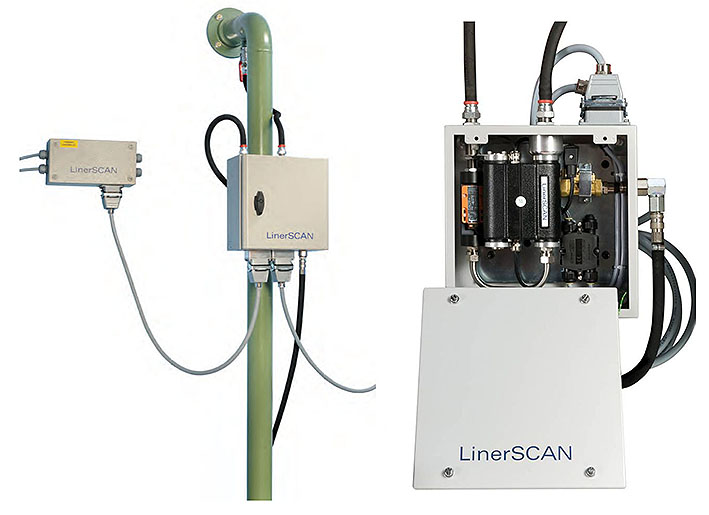

LinerSCAN

LinerSCAN provides highly accurate feedback on the wear condition of your engine. Trials have shown that LinerSCAN detects the first signs of damage earlier than other systems and allows the lubricant feed rate to be safely reduced. If the wear rate increases under normal conditions the system generates an alarm which, when linked to the ship’s alarm, provides instant feedback for immediate action. This allows preventive maintenance to be carried out while the ship is en route to the next port, or even on a change of route. LinerSCAN is a fully automated system and will help you save money by optimizing the lubricant feed rate, reducing your maintenance burden and preventing unnecessary engine damage.

XRF Analyser

The ability to spot check the sulphur content of fuel oil on board a vessel will help ship owners and operators ensure compliance with the latest IMO (MARPOL) regulations. Every machine maintenance professional has heard of or applied the practice of Machine Condition Monitoring, Proactive Maintenance, Condition-Based Maintenance, Predictive Maintenance, Equipment Vibration Monitoring, etc.

All of these philosophies help to prevent unplanned breakdowns and maximize equipment availability. All require buy-in at the plant equipment maintenance level, an efficient system, and timely information.

Whether online or on-site, even in the most remote and challenging environments, Parker has a maintenance system for you.

By the way … Non-hazardous version available for shipping water in oil cell when you see the EasySHIP logo

Karberg & Schmitz

Water treatment on river cruise ships

With the opening of our service station in Dernbach (located between Cologne and Koblenz), we are close to one of Germany’s lifelines, the river Rhine.

Our mobile teams of experienced service engineers take on the challenge of following your cruise vessel or even being ahead of your ship in the next harbour to provide the required services before the vessel leaves again. Our cars are equipped with all the necessary tools and materials to service the water makers and surrounding systems as such:

- RO units

- UV sterilizes

- Water softener

- Bunker water chlorination

- Drinking water treatment

- Pool water treatment

Some of the maintenance and repairs we regularly carry out:

- Regular maintenance and overhauls

- Replacement of membranes and filters

- Replacement of pumps, motors, valves and other parts

- Repairs to pipelines or mechanical components

Where we go

We provide our services within Germany, Austria and France for ships sailing on the Rhine, Moselle and Danube.

Oil Filtration

Under development